Rigid boxes have become the gold standard in luxury product presentation, offering unmatched elegance, durability, and brand appeal. Whether you’re a premium brand in cosmetics, fashion, tech, or gourmet foods, your packaging says as much about your product as the product itself.

In this complete guide, we’ll walk you through everything you need to know about rigid boxes, from structure types and surface finishes to customization processes and quality control, so you can make informed packaging decisions that impress your customers and elevate your brand.

What is a Rigid Box?

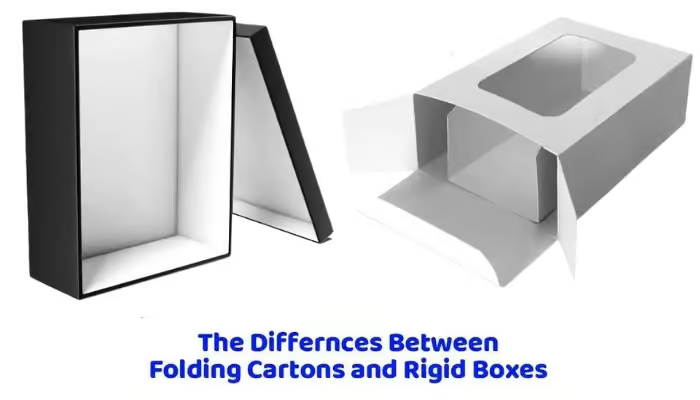

A rigid box is a high-end packaging structure made from thick, compressed paperboard (commonly 1.5mm–3mm), wrapped in decorative paper, fabric, or specialty coatings. Unlike folding cartons, rigid boxes do not collapse, offering a firm and luxurious structure that enhances product value and shelf presence.

Key Features

Rigid boxes are defined by their superior construction quality, precision finish, and structural rigidity. As a physical packaging solution, they offer several core characteristics that distinguish them from other box types:

- Thick and rigid base material: Constructed from chipboard or greyboard, typically ranging from 1.5mm to 3mm in thickness, providing excellent strength and shape retention.

- Non-collapsible structure: Unlike folding cartons, rigid boxes are pre-assembled and maintain their shape, offering a consistent luxury experience from shelf to unboxing.

- Wrapped outer surface: The outer layer is laminated with specialty paper, art paper, fabric, or textured finishes, allowing seamless branding, high-resolution printing, and tactile customization.

- Precision edges and alignment: The assembly process results in sharp corners, clean edges, and minimal glue lines, reinforcing a high-end visual and tactile standard.

- Compatible with premium inserts: The rigid body can house EVA foam, velvet lining, molded trays, or multi-layer compartments for both protection and upscale display.

Rigid Box vs. Folding Carton: Which is a Better Choice for Luxury Packaging?

Choosing the right packaging solution is vital to product positioning. Here’s how rigid boxes compare to folding cartons across four key areas:

Appearance

Rigid Boxes immediately convey a sense of exclusivity. Their substantial weight, clean edges, and seamless wrapping create a premium visual and tactile experience that aligns with high-end branding.

Folding Cartons, although visually customizable, typically lack the depth and solidity of rigid boxes. Their thin paperboard construction may appear flimsy, especially when paired with heavy or expensive products.

Material

Rigid boxes are built using thick chipboard (typically 1.5mm to 3mm), wrapped with decorative paper or specialty finishes. This gives them a solid, non-collapsible structure that protects products while preserving the box shape even after repeated handling.

Folding cartons are made from lighter 250–600gsm paperboard, which is easily foldable and lightweight, ideal for mass-market products but not sufficient for high-end presentation or impact protection.

Cost

Rigid boxes are more expensive due to thicker materials, labor-intensive assembly, and often manual finishing. However, the investment pays off in perceived value and brand differentiation for luxury markets.

Folding cartons are cheaper and faster to mass-produce, making them ideal for price-sensitive or promotional packaging, but not necessarily suitable for high-end product positioning.

Shipping

Rigid boxes are pre-assembled and non-collapsible, which means they take up more space during shipping and warehousing, increasing logistics costs.

Folding cartons ship flat, making them extremely space-efficient and cost-effective for global distribution. They’re better suited for high-volume, lightweight items.

Comparison Table of Rigid Box vs. Folding Carton

| Criteria | Rigid Box | Folding Carton | Best for Luxury? |

| Appearance | Premium, solid, tactile | Lightweight, flat | Rigid Box |

| Material Strength | Thick (1.5–3mm chipboard) | Thin (250–600gsm paperboard) | Rigid Box |

| Unit Cost | Higher, hand-assembled | Lower, mass-produced | Folding Carton |

| Shipping Efficiency | Bulky (non-collapsible) | Ships flat, efficient | Folding Carton |

| Product Protection | Excellent | Basic, unless combined with inserts | Rigid Box |

If your brand is positioned in the luxury market or aims to enter it, rigid boxes are the superior choice for delivering unforgettable packaging, strong protection, and premium brand value.

7 Types of Rigid Box Structures

Choosing the right rigid box structure is not just about aesthetics; it’s about creating the perfect balance between brand experience, product protection, and practical usability. In luxury packaging, structure plays a vital role in storytelling, customer interaction, and product positioning.

Magnetic Closure Rigid Box

This is one of the most popular luxury packaging structures. It features a hinged lid with magnet inserts that allow the lid to snap shut securely and smoothly. The closing motion feels elegant and deliberate, creating a satisfying unboxing moment.

These boxes typically have a book-style or clamshell design and are used for high-end items like electronics, perfumes, custom gift sets, and influencer kits. Magnetic closure boxes are easy to open and close while maintaining a clean, premium appearance.

Drawer-Style Rigid Box

Also known as a slide box or matchbox-style box, this structure consists of a sleeve and an internal tray that slides out from one side, often with a ribbon pull or finger notch. It feels interactive and luxurious, turning the unboxing process into a layered experience.

Drawer-style boxes are ideal for jewelry boxes, watch boxes, tech accessories, and gourmet food items. They offer excellent protection and make a strong impression in retail or gifting scenarios.

Book-Style Rigid Box

Inspired by the shape and functionality of a hardcover book, this box opens from the side with a hinged lid attached to the base along the spine. To enhance the storytelling aspect, it often includes a magnetic closure, ribbon ties, or printed inner flaps.

Book-style rigid boxes are perfect for branding kits, luxury documents, special edition products, or collector’s items, as they offer space for inner compartments or booklet-style messaging.

Shoulder and Neck Rigid Boxes

This premium structure includes three parts: a base, a lid, and an inner tray (the “neck”) that connects the two. The shoulder can be fully or partially visible when the box is closed, depending on the design.

Shoulder boxes provide a clean, seamless look and a tight fit, making them suitable for perfume boxes, cosmetic boxes, fine jewelry boxes, and small electronics. The added inner layer also enhances rigidity and protection.

Hinged Lid Rigid Box

A hinged lid rigid box is similar to the book-style box, but typically without the extended spine or extra flaps. The lid is permanently attached to the back edge of the base and flips open vertically.

Widely used for luxury items, watch boxes, cosmetic boxes, and gift boxes, this box style elevates brand value, protects products, and offers a refined unboxing experience.

Collapsible Rigid Box

Also known as a foldable rigid box, this structure is designed with pre-scored folding edges and adhesive panels, allowing the box to collapse flat for shipping and storage. When assembled, it maintains the appearance and strength of a traditional rigid box.

Collapsible boxes are especially useful for e-commerce brands, international shipping, or seasonal campaigns where space and logistics matter, without compromising on a luxury feel.

Tube Rigid Box

This is a cylindrical rigid box, composed of a round body with top and bottom lids. The surface is usually wrapped with specialty paper or printed designs, and the structure creates a strong shelf presence.

Tube boxes are used for bottles (wine, oils, beauty serums), rolled goods (scarves, posters), and candles. Their unique shape stands out in crowded retail environments.

Custom Rigid Box: 5 Types of Finish for Luxury Packaging

In luxury packaging, the surface finish is what transforms a well-structured box into a premium brand experience. While the structure of a rigid box provides durability and function, it is the outer finish that delivers the visual impact, tactile impression, and emotional connection with the customer.

Let’s explore these finishing types and discover how they can elevate your custom packaging to match the expectations of luxury buyers.

Lamination

Lamination is one of the most widely used finishes in luxury rigid box production. It involves applying a thin protective film over the printed surface of the box to enhance appearance and durability. Depending on the effect you want, you can choose from matte, gloss, or soft-touch lamination.

- Matte lamination gives a refined, modern look with a smooth, non-reflective finish, perfect for minimalist or high-end branding.

- Gloss lamination creates a shiny, vibrant effect that enhances colors and visual contrast.

- Soft-touch lamination delivers a velvety texture that feels luxurious to the touch and reinforces the idea of premium quality.

Key Benefits:

- Enhances surface durability and lifespan

- Resists scratches, oil marks, and wear

- Soft-touch version improves tactile appeal

Foil Stamping

Foil stamping (also called hot foil or metallic foil stamping) is a technique where a layer of metallic foil, often gold, silver, copper, or holographic, is applied to the surface using heat and pressure.

This process creates a brilliant, light-reflective effect that draws attention to logos, text, or decorative elements, making it ideal for luxury goods where branding impact matters. Foil stamping pairs exceptionally well with embossing or matte lamination for contrast.

Key Benefits:

- Creates high-contrast, metallic effects

- Precise detailing for logos and icons

- Long-lasting and resistant to fading

Embossing and Debossing

Embossing and debossing create raised or recessed impressions on the box surface, adding a three-dimensional texture that enhances both visual appeal and touch.

- Embossing pushes the design outward, creating a raised surface.

- Debossing presses the design inward, creating an indented effect.

These techniques are often used for logos, brand patterns, or framing elements, especially when combined with foil stamping for added depth and contrast.

Key Benefits:

- Adds texture and tactile engagement

- Elevates perceived craftsmanship

- No additional materials or adhesives required

- Works well with specialty papers and minimalist designs

Spot UV

Spot UV (also known as UV coating) is a high-gloss varnish applied only to specific areas of the printed surface, such as a logo, image, or title, while leaving the rest of the surface matte or uncoated.

This creates a striking contrast between shiny and flat textures, capturing light and drawing the eye to key elements.

Key Benefits:

- Sharp, glossy highlights for selective emphasis

- Adds contrast without using foil or pigment

- Durable coating resists moisture and abrasion

Flocking

Flocking applies a soft, fabric-like coating to a surface or insert using fiber particles. Often used inside rigid boxes, especially for jewelry boxes, cosmetic boxes, or electronic packaging, flocking mimics velvet or suede, offering both protection and visual warmth.

Key Benefits:

- Adds soft, fabric-like texture to surfaces

- Provides cushioning and product protection

- Enhances luxury perception through material contrast

How to Customize a Rigid Box? Manufacturing Process

Customizing a rigid box isn’t just about choosing a size or color; it’s about aligning every element of your packaging with your product’s value, your brand identity, and your customer’s expectations.

For buyers such as brand owners and wholesalers, the challenge lies in translating a design concept into a structurally sound, visually striking, and cost-effective packaging solution that meets both functional and aesthetic demands.

Packaging Requirement Analysis

At Gentlever, we develop rigid box structures strictly based on the functional and physical requirements of the product.

We then determine the most suitable box structure, base material, and production method. This phase ensures all packaging components are technically feasible and aligned with your goals.

Our sales and engineering teams gather all essential parameters, such as:

- Product type, weight, and fragility

- Target market and customer expectations

- Application scenario: retail, gifting, influencer, or e-commerce

- Brand positioning: minimalist, artistic, luxurious, eco-conscious

Material Selection & Sustainability Planning

If your brand requires eco-friendly solutions, we can also offer fully recyclable packaging, plastic-free insert options, or minimalist mono-material designs.

We source and propose the most appropriate materials based on the structure, finish, and sustainability goals of your project. Our core rigid box materials include:

- Recycled greyboard for the core structure (FSC-certified available)

- Soy-ink printing and water-based coatings

- Paper wraps made from kraft, cotton paper, or stone paper

Choosing the right sustainable material helps enhance your brand image, especially for premium markets in Europe and North America, where eco-compliance influences buying decisions.

Graphic Design and Branding Elements

Your rigid box is a visual ambassador for your brand, and precise design execution is key to maintaining a consistent, high-end image. By preparing your design assets properly, you minimize production errors, reduce sampling rounds, and ensure your packaging reinforces your brand at every touchpoint.

Below are the essential visual elements to plan for during the customization process:

- Logo Placement: Decide whether the logo will be centered, corner-aligned, or span the entire lid. Consider visibility when the box is closed and opened.

- Typography Control: Use consistent brand fonts with clearly defined hierarchy. Avoid overly small text that may blur after printing.

- Color Consistency: Provide Pantone or CMYK values to ensure exact color matching across surfaces and finishes.

- Print-Ready Artwork: Supply vector files (PDF, AI, or EPS) based on the supplier’s dieline template, with bleeds, safety margins, and cutting lines clearly indicated.

Insert & Internal Structure Development

Depending on your product’s fragility and presentation style, our engineering team develops a matching insert that fits perfectly into the rigid box. Options include:

- EVA foam: Durable and protective; ideal for electronics and glass items

- Velvet-wrapped trays: Adds tactile softness and visual elegance

- Molded pulp/cardboard: Recyclable and cost-effective

- Die-cutting paperboard: Lightweight, customizable, and suited for multi-product layouts

Finalize Packaging Dimensions

We produce physical prototypes, including white samples, printed samples, and fully finished production samples, for your review and sign-off. This sample should be thoroughly reviewed to confirm fit, lid closure, magnet placement, and overall usability before printing or full production begins.

- Accurate internal measurements of your product (with clearance tolerance)

- Allowance for insert thickness and lid fit

- Structural strength based on weight and handling environment

How to Evaluate the Quality of a Luxury Rigid Box?

Ensuring your rigid box meets luxury standards goes beyond appearances; it requires evaluating structure, surface finishing, functionality, and material integrity. Each test focuses on a specific performance area: from the sharpness of print to the durability of the board, from closure precision to the strength of surface coatings.

The following checkpoints help you verify that your packaging not only looks refined but also performs reliably under real-world use.

Visual Quality Check

The first impression of luxury packaging begins with visual perfection. A high-end rigid box should display sharp edges, clean corners, aligned panels, and flawless surface wrapping. Any visual inconsistency, such as bubbling, creasing, or visible glue, can signal poor craftsmanship and degrade brand value.

Material Strength & Protection Test

Beyond appearance, a rigid box must physically protect the product inside. This means resisting pressure, bending, and accidental drops. Use manual testing to evaluate whether the box maintains its shape when handled, especially around the corners, lid, and base.

- Squeeze Test: Apply pressure to the sidewalls and lid; the box should not dent or collapse easily.

- Drop Test: Drop the box (with mock weight inside) from 0.8–1m to assess corner integrity and lid fit.

- Flexing: Open and close the box multiple times to detect any loosening or hinge fatigue.

These tests verify the strength and reliability of chipboard thickness, wrapping tightness, and construction method.

Surface Finishing Inspection

Luxury boxes often feature specialized surface treatments like lamination, foil stamping, or embossing. These finishes must be precisely applied and durable over time. Check whether finishes are properly aligned with the artwork and remain intact after handling.

You can perform a gentle rub test or moisture wipe to confirm the durability of the finish, especially important for boxes handled frequently or displayed in retail environments.

Closure & Opening Mechanism Test

The tactile feeling when opening a luxury rigid box is part of the experience, and poor closures can ruin it. Magnetic lids should snap shut smoothly and stay closed when lifted. Drawer boxes should slide evenly without catching, and shoulder boxes should separate with steady resistance.

Functional flaws not only affect user experience but can also lead to practical issues, such as accidental opening during shipping or product misalignment inside the box.

Work with Gentlever to Custom Rigid boxes for Brands

At Gentlever, we understand that luxury packaging is not just about boxes; it’s about helping brands deliver experiences, express identity, and build lasting customer impressions. That’s why we go far beyond simple manufacturing. We offer strategic custom packaging solutions tailored to your product, market, and supply chain goals.

Every box is crafted from structural design to surface finishes to match your brand’s tone, color system, and positioning. Whether you need magnetic closures, shoulder-neck styles, or drawer formats, we produce packaging that reflects who you are and what your customers expect.

With flexible MOQs and global shipping support, we serve clients across Europe, North America, and Asia. Contact us today for a tailored quote, and let us help elevate your packaging to match the value of your brand.

Conclusion

Rigid box packaging offers strength, elegance, and customization, making it the ideal choice for premium products and luxury branding. From structure types and surface finishes to full customization and quality control, choosing the right packaging partner is essential.

At Gentlever, we specialize in delivering high-quality custom rigid boxes with competitive pricing and full-service support for global clients.

Ready to upgrade your packaging? Contact us today for a free quote or consultation, and let us help you create rigid boxes that impress, protect, and sell.