Foil stamping is a popular finishing technique used to add metallic shine and premium detail to luxury packaging.

This guide explains what foil stamping printing is, how the process works, the types of foil and finishes available, and where it’s commonly applied. You’ll also learn how to design an effective foil-stamped box and why working with the right packaging supplier makes all the difference.

What Is Foil Stamping?

Foil stamping is a premium printing technique that uses heat, pressure, and metallic or pigmented foil to create stunning, high-contrast designs on packaging. It is commonly used in luxury box production to elevate branding, add visual richness, and convey a sense of exclusivity. Unlike regular ink printing, foil stamping reflects light and adds texture, making it ideal for logos, accents, and statement elements.

In the competitive world of luxury product packaging, visual appeal is critical. Brands in cosmetics, jewelry, fashion, and gift industries often choose foil stamping printing because it immediately communicates sophistication and value. This finishing method not only boosts shelf presence but also enhances the tactile experience — a key factor in premium unboxing.

How Does the Foil Stamping Process Work?

The foil stamping process involves several precise steps. Understanding how it works helps buyers and designers collaborate effectively with packaging suppliers and make informed decisions.

Step 1 – Custom Die and Foil Preparation

To begin, a metal die is created based on the client’s design — typically a logo, brand name, or decorative graphic. This die is engraved using magnesium, copper, or brass, depending on detail and production volume requirements. At the same time, a specific foil roll is selected based on finish type (metallic, matte, holographic, etc.) and color.

Step 2 – Heat and Pressure Transfer

Using a foil stamping machine, the die is heated to a controlled temperature. The packaging material (usually rigid box surface or paperboard) is positioned beneath the foil and die. Through a combination of heat and pressure, the foil is pressed onto the surface, permanently bonding the design to the material. For multi-layer or multi-color foil effects, this step is repeated with different dies.

Step 3 – Surface Finish and Quality Control

After stamping, the surface is inspected for sharpness, consistency, and alignment. A high-quality foil stamp should be smooth, crisp, and evenly transferred with no gaps, ghosting, or excess foil. Optional post-processes like lamination, embossing, or varnishing may follow depending on the desired finish.

What Are the Different Types of Foil Stamping?

Foil stamping techniques vary depending on design complexity, box structure, and production scale. Here are the most common types of foil stamping printing:

Flat Foil Stamping

Also known as flatbed stamping, this method uses a flat die to press foil onto a flat surface. It’s the most widely used approach for rigid boxes, offering excellent accuracy and flexibility for most designs.

Vertical Foil Stamping

This traditional method involves a vertical press and is often used for small to medium batches. It’s cost-effective and versatile, but slower than modern automated machines.

Sculpted Foil Stamping

This high-end technique uses a 3D sculpted die to create raised, textured foil impressions. It adds both shine and dimension, making it ideal for premium logos and high-value packaging.

Peripheral Foil Stamping

Used for curved edges or circular surfaces, this technique allows foil stamping around the perimeter of round containers or lids.

Round-to-Flat Foil Transfer

A hybrid approach that enables hot foil stamping on cylindrical objects that are flattened temporarily during application, suitable for specialty tube packaging.

Rotary Stamping

Ideal for high-speed, large-volume production, rotary stamping uses cylindrical dies and continuous motion presses. It delivers consistent results on folding cartons and wrap-around packaging.

What Are the Most Popular Foil Finishes?

Choosing the right foil finish is essential to achieving the desired visual effect and brand tone. From classic metallics to modern holographics and soft matte options, each foil type offers a distinct look, texture, and impact that can enhance the appeal of your luxury box design.

Metallic Foils

Gold and silver foils are timeless choices for premium appeal. These reflective finishes exude elegance and are widely used in cosmetics, jewelry, and premium electronics packaging.

Matte Foil

Matte foil offers a modern, understated look. It absorbs light rather than reflecting it, ideal for brands that want elegance without too much shine.

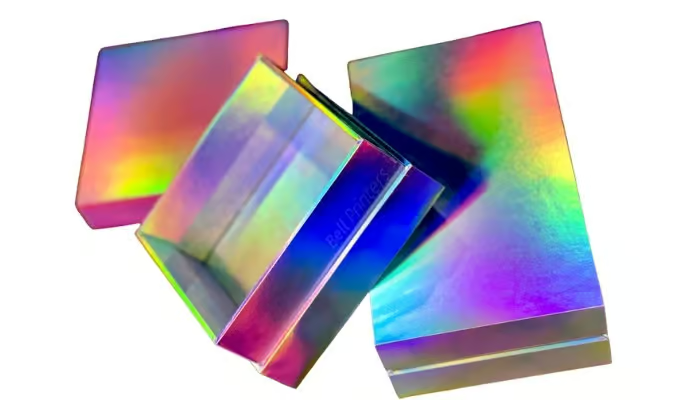

Holographic Foil

This multi-color, iridescent foil changes appearance under light, adding a futuristic or festive effect. Often used for promotional or limited-edition product packaging.

Pigment Foils

Available in solid colors like black, white, red, or blue, pigment foils provide sharp contrast and a smooth appearance without metallic effects.

Pearlescent Foils

These foils produce a soft, pearly sheen — a subtle luxury detail often seen in wedding packaging, skincare boxes, and high-end gift sets.

Clear Foils

Clear foils create a glossy effect without altering the base color. They’re often used for watermark-style branding or subtle accents.

How to Choose the Right Foil Finish

| Foil Finish | Key Benefit | Best Use |

| Metallic Foil | High-end visual impact | Luxury products, premium retail packaging |

| Matte Foil | Elegant and non-reflective | Minimalist and modern brands |

| Holographic Foil | Vibrant and eye-catching | Limited editions, youth-driven products |

| Pigment Foil | Strong contrast with solid color impact | Logo and text clarity |

| Pearlescent Foil | Soft shimmer, gentle luxury | Skincare, bridal, wellness items |

| Clear Foil | Invisible gloss, subtle branding | Understated elegance, sustainability focus |

Common Applications of Foil Stamping in Luxury Boxes Packaging

Foil stamping plays a critical role in premium packaging across industries where visual appeal, brand prestige, and consumer experience matter most. From global beauty brands to high-end fashion houses, foil-stamped boxes are used not just to package products, but to elevate them into luxury experiences.

Cosmetics and Beauty

In the beauty industry, packaging is often as important as the product itself. According to a study, 52% of consumers are likely to make repeat purchases from brands that deliver premium packaging. Foil stamping is widely used on skincare and cosmetics luxury boxes to convey elegance, trust, and luxury.

For instance, Estée Lauder frequently incorporates gold foil stamping on its premium skincare box designs, combining metallic finishes with embossed logos to reflect a sense of quality and heritage. Similarly, Fenty Beauty uses holographic foil on its limited-edition kits to appeal to younger, trend-driven consumers.

Luxury beauty brands also combine foil stamping with soft-touch lamination and debossing to create a tactile, immersive unboxing experience, especially important in e-commerce and influencer marketing.

Jewelry, Watches, and Fashion

Foil stamping is a go-to technique in jewelry and watch packaging, where perceived value and craftsmanship must be reflected instantly through the box. Rigid boxes with silver or rose gold foil are used to elevate branding, while sculpted foil adds dimension to monograms and symbols.

Tiffany & Co. uses subtle silver hot foil stamping on the inside of its iconic blue boxes for branding consistency without overpowering the clean aesthetic. Independent watch brands like MVMT utilize matte black rigid boxes with glossy foil logos to create a minimalist, modern feel.

For luxury fashion accessories such as belts, bags, or scarves, gold foil accents are commonly added to drawer boxes or magnetic closure boxes to signify exclusivity, especially in boutique or limited-release packaging.

Gift Sets and Collector’s Items

Seasonal gift sets and collector’s edition packaging benefit greatly from the drama and visual impact of foil stamping. In the collectibles and memorabilia space, foil stamping is also a standard in packaging limited-run products.

From luxury stationery sets to exclusive sneaker drops packaging, multi-foil layers, and holographic effects help drive scarcity and elevate perceived uniqueness.

Why Choose Foil Stamping for Your Luxury Box Design?

In an era where visual identity directly influences buying behavior, foil stamping is no longer just a decorative element; it’s a strategic branding investment. Luxury consumers expect more than quality products; they expect packaging that speaks to elegance, attention to detail, and brand prestige.

Boosting Brand Visibility and Identity

In crowded retail spaces or online marketplaces, standing out is a challenge. Foil stamping draws attention instantly by reflecting light and creating contrast against background materials. A study by the Paper and Packaging Board found that 72% of consumers believe product packaging design influences their purchase decisions.

Gold, silver, or holographic foil logos increase visibility while reinforcing brand prestige, especially for high-end cosmetics, jewelry, or fashion brands. Foil stamping also elevates your logo from a printed graphic to a distinctive brand asset with lasting visual impact.

Creating a Luxurious Look and Feel

When consumers associate your packaging with elegance, quality, and attention to detail, they also assign those qualities to your product. Foil stamping adds texture, shine, and contrast, triggering positive sensory responses.

Luxury brands often combine hot foil stamping with soft-touch lamination or embossing to create a full-sensory unboxing experience. This not only pleases the customer but also makes the product more “giftable” — a key driver in industries like skincare, home fragrance, or gourmet food.

Long-Lasting Finish for Premium Packaging

Unlike standard ink printing that may fade or scuff during shipping and shelf display, hot foil stamping offers long-term durability. Once transferred, the foil is resistant to wear, oxidation, and color fading.

For rigid box designs used in luxury sectors — especially those meant for display, reuse, or gifting — this long-lasting finish helps ensure your packaging maintains its premium look well beyond purchase. This is particularly valuable for subscription boxes or brand collaborations that need to retain visual quality across multiple customer touchpoints.

Compatible with a Wide Range of Packaging Styles

Foil stamping is extremely versatile and can be applied to a variety of box structures, including drawer boxes, magnetic closure boxes, two-piece rigid boxes, and foldable cartons. It also works well across different surfaces — coated paper, textured board, kraft paper, or even recycled materials, making it suitable for both luxury and eco-conscious brands.

Whether you’re designing minimalist skincare packaging or an ornate holiday gift luxury box, foil stamping adapts easily to your brand’s visual language and box engineering requirements.

Enabling Bold and Innovative Design Accents

Beyond logos and text, foil stamping allows for creative expression through patterns, borders, icons, and layered finishes. Brands can use multiple foil colors in a single design, integrate sculpted foil for 3D depth, or combine foil stamping with embossing to create truly dynamic textures.

For limited editions or seasonal packaging, foil stamping becomes a tool for storytelling — creating excitement and collectibility. GlobalData notes that effective packaging helps brands engage modern consumers, particularly in the prestige beauty sector。

How to Design a Custom Foil-Stamped Luxury Box

Creating a foil-stamped luxury box requires more than visual appeal — it involves smart decisions about structure, materials, and design execution to ensure both beauty and performance. This section walks you through how to choose the right box style, surface material, and foil design strategy for optimal results.

Popular Box Structures for Hot Foil

The first step in foil-stamped packaging design is choosing the right box structure. Certain styles are more compatible with foil stamping depending on how and where the foil will be applied.

- Rigid Magnetic Closure Box

Often used for cosmetics, electronics, and premium gifts. Its flat lid surface is ideal for large foil logos or wraparound foil borders. - Drawer Box (Slide Box)

Offers a premium unboxing experience with a hidden reveal. Foil stamping can be applied on the outer sleeve, inner drawer, or pull tab. - Two-Piece Setup Box (Lid + Base)

A classic luxury structure. Perfect for central foil placement on the lid and complementary foil accents on the base or inside flaps. - Foldable Carton Box

Lightweight and shipping-efficient. With proper scoring and lamination, foil stamping can still achieve a strong visual impact.

Tip: The flatter and more rigid the foil area, the better the stamping result. Avoid placing foil designs near deep folds, box seams, or over structural creases.

Surface Materials and Foil Compatibility

Your choice of surface paper or board dramatically affects how well the foil adheres and how sharp the final result looks. At Gentlever, we offer tested materials optimized for foil applications.

- Coated Paper (Art Paper)

Smooth and reflective — ideal for sharp, clean foil lines. Common for beauty and retail rigid boxes. - Textured Paper (Linen, Touch-Feel, Embossed)

Adds tactile value but may require stronger pressure and bolder foil designs to maintain clarity. - Black Card or Color-Dyed Paper

Often used with gold or metallic foil for high contrast. Ideal for jewelry and high-end branding. - Kraft or Recycled Board

Compatible with white foil, matte foil, or clear foil for a natural luxury look. Works well for eco-conscious brands.

Recommendation: Always test your selected paper + foil combo with a real sample. Factors like absorbency, surface fiber, and lamination can affect transfer quality.

Key Foil Design Considerations

Even with the best foil and materials, design execution is critical. Here are essential factors to keep in mind during the artwork phase:

- Avoid ultra-thin lines and very small text

Foil can’t achieve the same fine resolution as digital or offset print. Minimum stroke width should be around 0.3mm or more for metallic foils. - Keep registration tight

If combining foil stamping with embossing, debossing, or multi-color printing, precise alignment (registration) is crucial to avoid visual mismatch. - Limit large foil coverage areas

Excessively large foil blocks may appear uneven or may not transfer cleanly, especially on textured papers. - Use vector-based artwork for die creation

Files should be submitted in high-resolution PDF or AI format with separate foil layers clearly marked. - Combine with other finishes wisely

Foil stamping pairs well with embossing, spot UV, and lamination. Plan your finishes to complement—not compete with—each other.

Why Choose Us as Your Foil Stamping Box Supplier

At Gentlever, we go beyond standard foil stamping by offering eco-conscious materials, complex box structures, and full-process packaging integration — all tailored for global business clients.

From recyclable kraft board to textured FSC® paper, we help you align luxury packaging with sustainability goals. Our foil stamping applies not just to rigid gift boxes, but also to foldable boxes, e-commerce mailers, and multi-panel designs, giving your brand more creative flexibility across product lines.

Combined with optional finishes like spot UV, embossing, and soft-touch coating, we ensure every box reflects your brand’s value from every angle.

With fast sampling, low MOQs, and export-ready support in English, we make it easy for you to create standout custom packaging that delivers on both design and delivery.

Conclusion

Foil stamping is one of the most powerful tools in luxury packaging, blending tactile appeal, visual drama, and brand storytelling into a single element. Whether you’re launching a high-end cosmetics line, releasing a holiday gift set, or refreshing your retail presence, a custom foil-stamped luxury box can dramatically elevate your product’s perceived value.

Partner with Gentlever to bring your luxury box ideas to life. Contact us today for a free consultation or quote.